Graham Hart Process Technology is a Bradford-based heat exchanger design and manufacturing specialist. First granted Fit For Nuclear in 2014, the team have built on their experience and were recently granted Fit For Hydrogen and CCUS status.

Managing director Chris Hart and technical director Charles Byrne share how they have ensured a 100 per cent on-time in-full delivery record for their clients since 2016.

Chris Hart:

In 2014, I remember sitting in an office with our industrial advisor. We were working on lean manufacturing, as part of the Fit For Nuclear programme with the Nuclear AMRC. I was appalled to discover our then score for on-time in-full (OTIF) delivery and, much to everyone’s disbelief, I said that we should target a score of 95 per cent next year. Through a lot of hard work, in 2015 the team achieved an OTIF of 98 per cent – and as they say, the rest is history.

We’re often asked by clients about our 100 per cent OTIF record and how we can ensure we’ll honour it for their order.

As a starting point, we will never offer a delivery that we cannot achieve on paper. Knowing our clients programmed dates, we always offer a realistic and best delivery date which can be adjusted to include overtime and weekend working where necessary, without compromising the end goal.

We rely on five key elements to meet our production schedules:

- Our committed workforce, their combined experience and attention to detail.

- A positive working relationship with all the Approved/Notified Bodies we progress our designs through.

- A reliable and continually assessed set of material suppliers and subcontractors.

- A purpose built inspection and test plan, to enable our client to routinely check progress and request photos and videos as each task is completed.

- Regular and planned communication with our client in the form of meetings, progress reports, schedule reviews etc.

These elements form the basis of our 100 per cent statistic of OTIF for every delivery since 2016, which we’re incredibly proud of.

Charles Byrne:

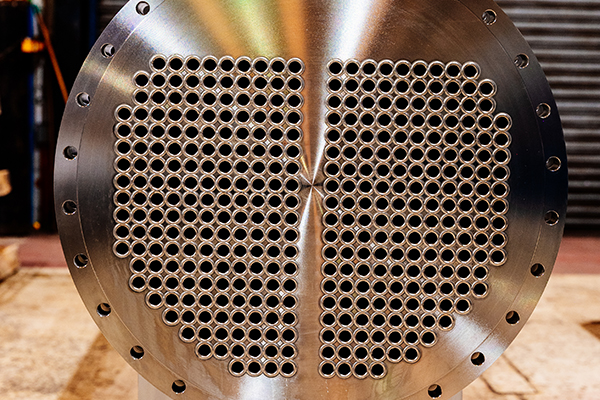

We do not mass produce any of our products. Our units are bespoke for each project incorporating unique design sizes, ratings, construction, NDT and testing. As such, there is no existing inventory or work in progress to draw upon or contribute to OTIF.

We operate a dynamic scheduling system which enables us to react quickly to issues with supply, subcontract operations or interested parties. The ability to respond to differing levels of need on each project enables us to manipulate schedules to ensure that each project can still attain OTIF

Achieving OTIF is not comfortable or easy. We have learnt through painful experience that any bespoke project involving a large number of sequential operations rarely goes to plan. However, strong partnerships and excellent working relationships helps us to achieve and retain our OTIF statistic.

The Nuclear AMRC were of huge assistance to us as we worked through the F4N process. Among the many critical areas they helped with was linking us up with industry experts to assist in exercises such as value stream mapping, which enabled us to almost halve our production times through parallel processing and better communication systems within our company.

One of the ways we give our clients, suppliers and colleagues confidence in our ability to deliver on our company values of being safe, professional and innovative, is our accreditations. We are certified to ISO45001, ISO14001 and ISO9001, and we also carry the ASME U-Stamp.

All of these qualifications demonstrate our commitment to maintaining the highest standards in occupational health and safety, environmental and quality management. We have also recently become an accredited member of the Good Business Charter and the Made in Britain manufacturing community.

Joining the F4N process was one of the best decisions we ever made.